Taiwan SME Drives Dual Transformation to Deliver Precision, Durability, and Sustainable Automation

Founded in 1985, TENSO Machinery Ind. Co., Ltd. is a Taiwanese manufacturer specializing in injection automation robots. All series robots have passed the EU CE safety certification, covering relevant CE directives on mechanical safety, EMC, and low voltage standards.

“Ensuring that every robot meets the world’s highest standards for reliability, safety, and sustainability is our mission,” said Ivan Chen, Marketing Manager at TENSO.

The company employs fully automated robotic welding to achieve consistent, high-precision quality across its product lines.

Daily Tested, Never Stop Improving

Guided by its philosophy of “Daily tested, Continuous Improvement,” every robot undergoes ten rigorous tests prior to delivery, covering structural endurance, vibration resistance, safety interlocks, and energy performance. These measures ensure CE/ISO compliance while directly contributing to ESG goals, including:

Optimizing systems for higher energy efficiency

Strengthening safety design to protect workers

Extending product lifespan to reduce e-waste and carbon footprint

Driving Low-Carbon and Smart Transformation

In 2025, with support from the Small and Medium Enterprise and Startup Administration (SMESA) under Taiwan’s Ministry of Economic Affairs and guidance from the Plastics Industry Development Center (PIDC), TENSO accelerated its low-carbon and smart manufacturing strategy.

“Our robotic arms are designed for a future of intelligent and low-carbon manufacturing,” Chen noted. “They are the essential hands that help industries transform.”

Through this initiative, TENSO assessed its organizational greenhouse gas emissions, identified key manufacturing hotspots, and formulated strategies for low-carbon transformation, activating an automation engine for sustainable manufacturing and becoming a trusted partner for industries worldwide pursuing carbon reduction.

Key customer benefits include:

Safety: Reduced labor risks and improved workplace safety

Cost Efficiency: Less downtime and lower maintenance costs

System Integration: Seamless connectivity with MES/WMS for full digital traceability

Low Carbon: Extended equipment lifespan to reduce emissions and resource use

Sustainability Partnership: Supporting supply chain ESG goals and performance

Proven Across Industries

TENSO Machinery delivers smart automation solutions that help enterprises integrate ESG principles while ensuring stable operations. With 40 years of experience, robots are deployed across industries from automotive and electronics to food packaging and medical devices, serving as a trusted partner for intelligent, low-carbon, and energy-efficient production.

Continuous Innovation: “Injection & Take-out in One”

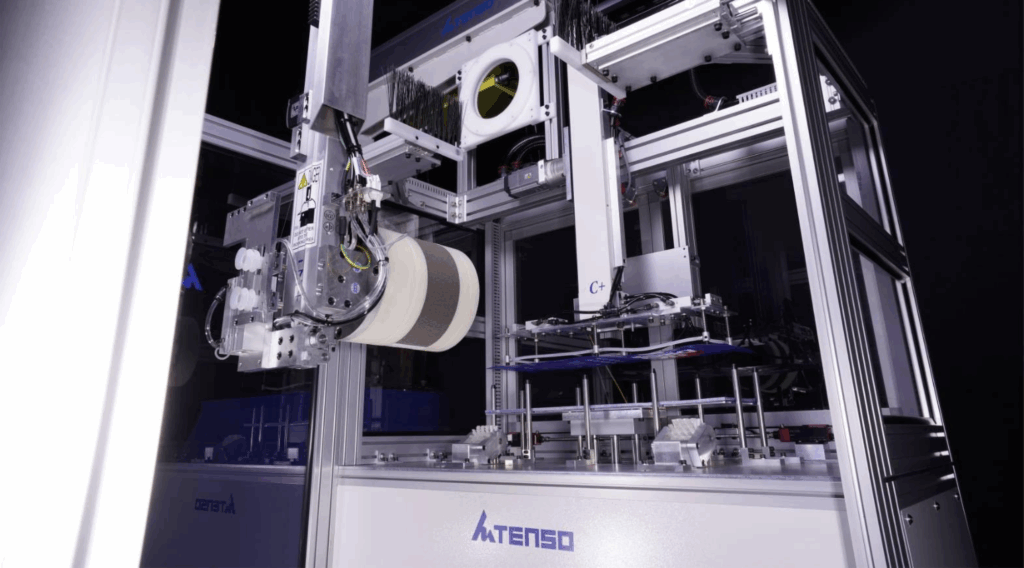

To drive continuous improvement, TENSO developed the “Injection + Take-out” system, which enhances equipment efficiency by automating part removal, stacking, and sorting. This reduces safety risks, increases uptime, enables 24-hour non-stop production, and shortens start-up stabilization from 30–120 minutes to near-immediate steady output—significantly improving yields.

The system also supports post-processing such as deburring, gate cutting, laser marking, and in-mold labeling. With interlock safeguards and error-proofing features, including automated QC checks and removal alerts, prevents mold damage and ensures high-quality, reliable production.

Mission for the Future

“TENSO’s mission is to enable quality through process equipment while helping industries achieve energy efficiency and carbon reduction.”