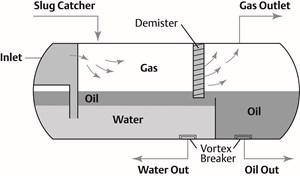

Fig. 1. Oil separators at remote sites exploit the difference in specific gravity to separate incoming well fluids into gas, oil and water. A separation failure can cause lost product and limit site production.

Oil separators are the mainstay of upstream petroleum operations. Their task is relatively simple, yet crucial for site operations. The oil separator vessel receives a three-phase mix of oil, water and gas from the wells and separates them, so they can be processed and recovered. When process control is upset, product can be lost and downstream equipment can be fouled, often requiring throughput to be significantly reduced to improve control.

Recently, an upstream petroleum facility in Canada was encountering serious reliability issues with its oil separator. Continuing problems required several service calls per month, and throughput was significantly curtailed. This article discusses some simple instrumentation upgrades that not only eliminated reliability problems but also significantly increased production.

OIL SEPARATOR LEVEL CONTROL OPERATIONS

Three-phase separators are very common at many well sites, Fig. 1. The vessel is a simple device consisting of a series of baffles and weirs that separate the mixed phase feed stream into gas, oil and water, so it can be efficiently transported to downstream operations for further processing. The liquid/vapor mixture from the wells enters the left side of the vessel, where liquids quickly disengage and fall to the bottom. The gas vapors exit via overhead piping, and the liquids separate, with the oil floating on top of the water.

One of the most critical measurements for an oil separator is the oil/water interface level on the left side of the tank. If the interface level drops too low, oil will leave with water and likely be lost. If the interface level rises too high, water will flow over the weir and go to oil processing equipment, which is not designed to handle water.

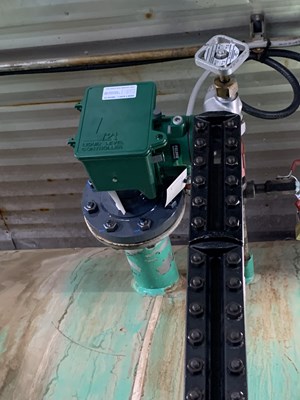

Fig. 2. The recently introduced Fisher™ FIELDVUE™ L2t Liquid Level Controller from Emerson is a cost-effective replacement option for existing pneumatic controllers. It can be installed through a 2-in. hole in the side of a horizontal oil separator vessel, or through the top of a vertical vessel.

Generally, the interface controller measures the interface and adjusts the outgoing water flow to keep the water level at or near the middle of the weir. The process must be stable, because if the oil separator cannot keep up, well production flows will be throttled to make separation easier and more reliable. This can solve separator problems, but it results in reduced site production.

PROBLEMATIC PROCESS CONTROL

A remote well site in Alberta, Canada, was struggling with constant problems with the separator operation. The interface was controlled with an old pneumatic controller and control valve that had been in operation for decades. Unfortunately, the pneumatic controller was becoming increasingly unreliable, requiring 23 service calls in a single year. Uptime for the site was around 93%, and throughput was decreased to reduce separator loading and minimize process upsets.

The site began investigating options for replacing the interface controller and consulted Spartan Controls, an Emerson Impact Partner, and their local automation provider, for a solution. Site personnel and the provider realized that an electronic controller could provide superior control, while also providing a means to remotely access and monitor separator operations. After reviewing their options, they settled on an electronic controller that had been designed as a direct replacement for pneumatic controllers and required no modifications to the vessel, Fig. 2.

Fig. 3. The replacement controller was installed in the existing nozzle, so no vessel or piping modifications were required.

The controller uses displacer technology to measure level, which is well-suited for oil separator service. It also can regulate operation, using traditional on/off or continuous control to provide a steady flow to downstream operations, Fig. 3, Reference 1.

The site team then turned its attention to the pneumatic control valve that was regulating the interface level. Spartan Controls application experts performed sizing calculations that showed how the valve was a significant bottleneck for operations, so plant personnel replaced it with a larger capacity valve and a digital positioner, Fig. 4.

The new equipment was installed during the site outage, with assistance from the local automation provider, and it was commissioned in short order.

The L2t device’s level measurement and control signal was transmitted to the new control valve to adjust water flow, and the controller level was also transmitted via a second analog signal to the control room for remote monitoring.

DRAMATICALLY IMPROVED OPERATIONS

The new equipment was placed into service, and the site immediately noticed significant operational benefits. Performance and maintenance issues related to the interface reading went from 23 incidents a year to zero, and separator uptime immediately jumped to 99-plus percent. Separator control improved dramatically, allowing the site to take full advantage of the higher capacity valve, while increasing production significantly. These improvements resulted in a very quick return on investment.

CONSIDER ALTERNATIVES

Fig. 4. Replacing the existing control valve with a newer model dramatically increased separator throughput.

If your well site is struggling with oilfield separator issues or interface measurement reliability, it may be time to consider an upgrade. This is especially true, if your site uses natural gas-fed pneumatic instruments, which emit significant greenhouse gases during operation.

Many existing separators use on/off control schemes, resulting in poor level control and an unstable oil/water interface. An unstable interface leaves more water in the oil and vice versa. A positioning control scheme as described in this article will create a much more stable oil/water interface.

There are no zero-emission level interface controller alternatives that can usually fit in the existing vessel nozzles with no modification. The control options for digital controllers are greatly expanded, and the improved reliability and ability to provide data for remote monitoring can create dramatic improvements in the site’s profitability. In this case, a simple and inexpensive upgrade increased site uptime and production volume dramatically.

All figures courtesy of Emerson.

REFERENCE

Process Instrumentation Q4 (Oct) 2023, Improved Oil Separator Control Strategies—Kurtis Jensen: https://www.piprocessinstrumentation.com/instrumentation/article/53074451/improved-oil-separator-control-strategies

MICHAEL COWAN is a technical sales specialist with Spartan Controls, an Emerson Impact Partner, with 12 years of industry experience, specializing in instrumentation, valves and actuation. He is a recognized speaker and instructor at the Canadian School of Hydrocarbon Measurement and various post-secondary institutions, where he shares his expertise and insights with industry professionals and students. Mr. Cowan holds a certification as a certified Instrumentation Engineering Technologist, granted by the Northern Alberta Institute of Technology.

NOLAN VOLLSTEDT is a senior sales engineer with Emerson’s flow controls business, a postion he’s held since 2019. During the first three years of his career at Emerson, he was dedicated to serving Emerson Impact Partners and customers in the metals and mining industry, and he now primarily supports opportunities in the upstream and midstream oil and gas sector. Mr. Vollstedt holds a bachelor’s degree in chemical engineering from Iowa State University.