TBM based in Japan has signed an MoU with Vung Ang II Thermal Power LLC (VAPCO), which operates a coal fired power plant in Ha Tinh Province, Vietnam, and Viet Hai Trading and Transportation Co., Ltd., a leading construction company in the same province.

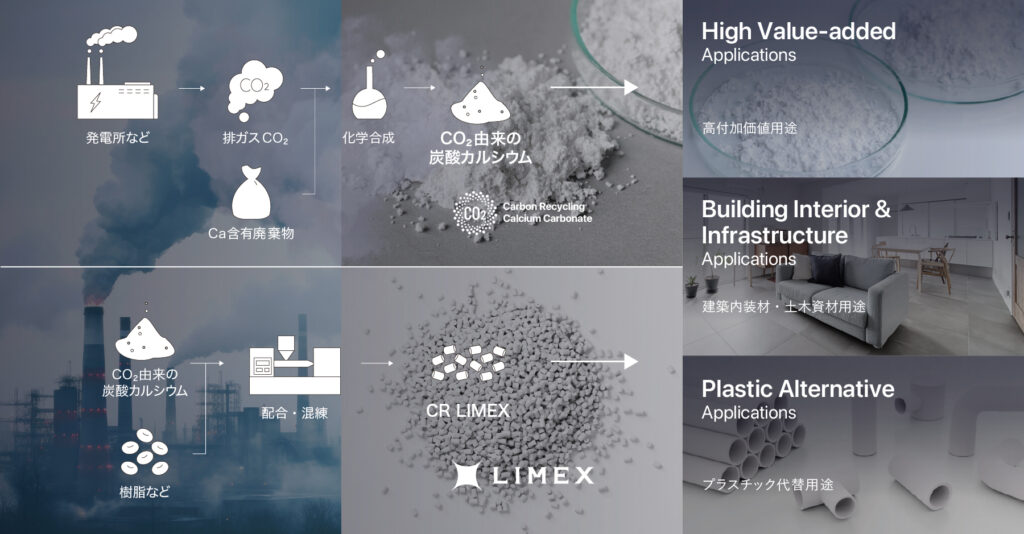

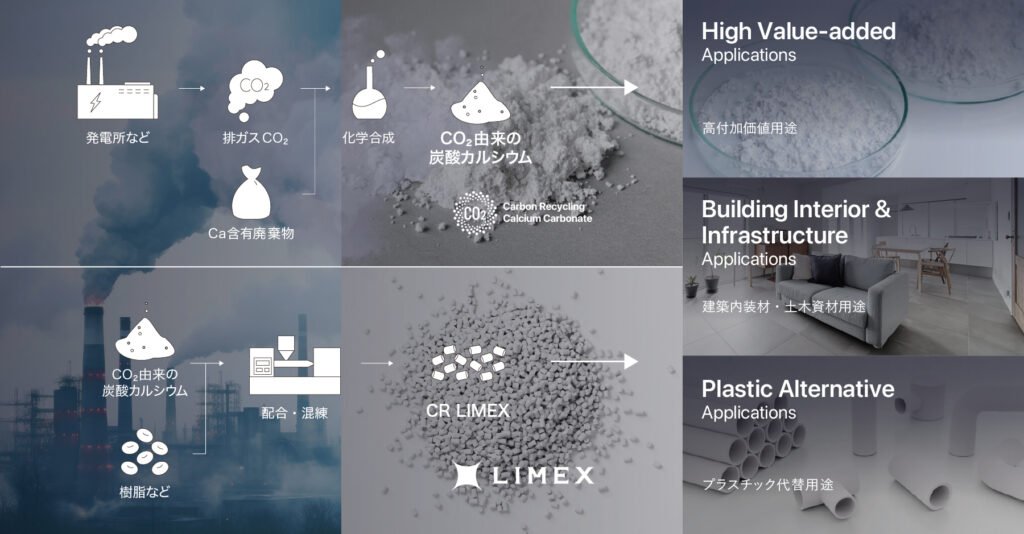

As well as calcium carbonate the companies will also manufacture “CR LIMEX” by compounding CCU Calcium Carbonate with resin and develop high value added applications for these materials.

As a next step the project will consider the construction of a CCU plant that captures and reuses approximately 160,000 tons of CO2 emitted annually from VAPCO’s thermal power plants. The plant will use TBM’s CCU technology to chemically synthesize approximately 400,000 tons of steel slag emitted annually from Viet Hai’s steelworks with CO2, with the goal of producing approximately 210,000 tons of CCU calcium carbonate per year. TBM will also consider the optimal method and infrastructure construction for producing CCU calcium carbonate using VAPCO’s CO2 and Viet Hai’s steel slag in Vietnam.

Vietnam has achieved solid economic development, recording a GDP growth rate of 7.09% in 2024, but the resulting greenhouse gas emissions have become a social issue. At COP26, the government declared its intention to achieve net-zero emissions by 2050. However, the share of coal-fired power generation in the country’s electricity mix remains high at approximately 55% (as of January 2024).

Under these circumstances, in order to advance decarbonisation without compromising the stable supply of electricity essential for economic growth, there is a need for solutions that reduce CO2 emissions through technological innovation while continuing to use existing power plants as important social infrastructure.

Under TBM’s CCU technology, which was introduced at the World Economic Forum Annual Meeting 2024 in Davos through the announcement of the CCU material CR LIMEX, TBM has developed a process to produce CCU Calcium Carbonate by chemically synthesizing CO2 with steel slag. CCU, which captures and reuses CO2, is positioned as one of the investment areas under the GX strategy promoted by the Japanese government.

The CCU Calcium Carbonate produced at the plant is planned to be used as construction materials in Vietnam and overseas through Viet Hai’s network. In addition, the partners plan to manufacture CR LIMEX by compounding CCU Calcium Carbonate with resin. By doing so, they aim to expand adoption in high value added applications beyond conventional calcium carbonate uses, including plastic replacement applications, interior building materials, and civil engineering materials.

The project aims to generate carbon credits by reducing CO2 emissions and by permanently storing CO2 that would otherwise be released into the atmosphere within products over the long term. In addition, the project will advance both resource circulation and carbon circulation by utilizing steel slag, an industrial byproduct generated during iron ore melting and scrap refining. Through these efforts, the partners will help accelerate the circular economy and carbon neutrality within the region.

Viet Hai will develop high-value-added applications for CCU calcium carbonate based on the technical and commercial information on CCU calcium carbonate provided by TBM and with TBM’s support in application development.