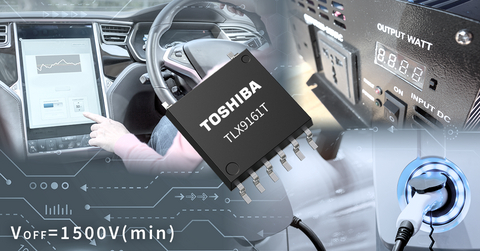

Toshiba Electronic Devices & Storage Corporation has launched an automotive photorelay[1], “TLX9161T,” in a small SO12L-T package, that achieves an output withstand voltage of 1500V (min), the level required to support high voltage automotive batteries. Volume shipments start today.

Key challenges in popularizing electric vehicles include reducing charging times and improving cruising range. Addressing these requires efficient operation of the battery system. This is done by the battery management system (BMS), which monitors the battery’s charge status to enable high-efficiency system operation, and also monitors isolation between the battery and the vehicle body to ensure the safe use of high-voltage batteries. Electrically isolated photorelays are used in BMS that handle high voltages.

Toshiba’s new product, a high-voltage photorelay with an output withstand voltage of 1500V (min), is a miniaturized version of Toshiba’s TLX9160T photorelay. Miniaturizing the TLX9160T’s built-in MOSFET chip has achieved integration into the SO12L-T package, which has a mounting area approximately 25%[2] smaller than the TLX9160T’s SO16L-T package. This size reduction also contributes to miniaturization and cost reduction of the BMS. The pin pitch and pin layout are the same as those of the SO16L-T, enabling use of the same circuit board pattern design.

The new photorelay uses a resin with a Comparative Tracking Index (CTI[3]) exceeding 600, which is classified under Material Group I[4] of the IEC 60664-1[5] international standard. The pin configuration ensures a creepage distance of more than 5mm[6] on the detector side. This realizes compliance with IEC 60664-1, supporting an operating voltage of 1000V.

Toshiba will continue to expand its lineup of automotive photorelay products and provide solutions that address the challenges in popularizing electric vehicles, aiming to contribute to the realization of a carbon-neutral society.